Many of our projects showcase ways our punched metal products are functional and aesthetically pleasing, but the majority of customers choose us purely based on the functionality portion of the equation. Because of our commitment to providing high-quality perforated metals and materials at reasonable prices, we are also well-known for our ability to produce custom-designed pieces for industrial manufacturing equipment. One such example is a large punched metal industrial order for GEM Equipment of Oregon, Inc.

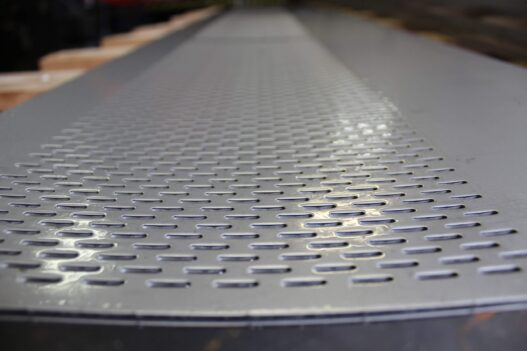

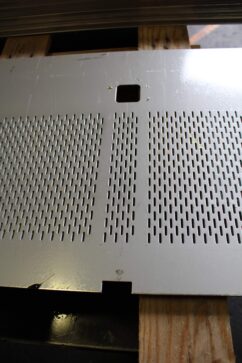

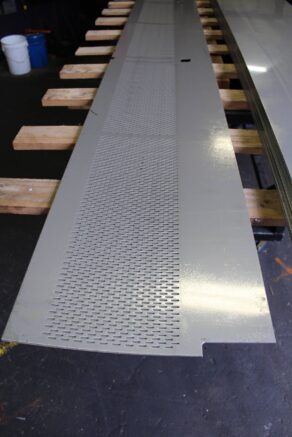

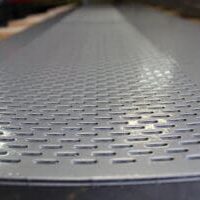

GEM Equipment frequently reorders punched metal sheets from Roy Manufacturing for installation in food processing equipment as part of an elevator that carries french fries up and out of a liquid bath. A total of 555 belts were produced from 14-gauge stainless steel: 300 sized 20.5 x 144” and 255 sized between 13 to 15 x 144”. Each sheet was punched with about 9000 obround/oblong holes sized 3/32 x 1/2”. A typical custom-punched metal industrial order is between 150 to 300 pieces, so we were excited to be selected for a project of this size!

GEM Equipment frequently reorders punched metal sheets from Roy Manufacturing for installation in food processing equipment as part of an elevator that carries french fries up and out of a liquid bath. A total of 555 belts were produced from 14-gauge stainless steel: 300 sized 20.5 x 144” and 255 sized between 13 to 15 x 144”. Each sheet was punched with about 9000 obround/oblong holes sized 3/32 x 1/2”. A typical custom-punched metal industrial order is between 150 to 300 pieces, so we were excited to be selected for a project of this size!

About GEM Equipment of Oregon, Inc.

Gem Equipment of Oregon. is a leading provider of custom-designed and built industrial food processing equipment and systems. With over 50 years of experience, the company has established a global reputation for quality and innovation in the industry.

Located in Woodburn, Oregon, GEM Equipment of Oregon, Inc. is a global leader in the food processing industry. Their commitment to innovation, quality, and customer satisfaction has earned them a reputation as one of the most trusted names in the industry. The company primarily focuses on safety, reliability, ease of maintenance, and the lowest ten-year total cost of ownership for each machine they design and build. GEM Equipment works closely with customers to ensure each machine is tailored to meet their needs and applications.

GEM Equipment’s product line includes a wide range of equipment, from augers and blanchers to fryers and vibrating conveyors. The company also offers complete mixed vegetable lines and pumping systems, ensuring they have the right solution for food processing needs.

From start-up to installation, GEM Equipment ensures that each machine is fully integrated into the customer’s manufacturing process, reducing ramp-up time and increasing production efficiency. The company is dedicated to ensuring the successful integration of its equipment into the customer’s operation.

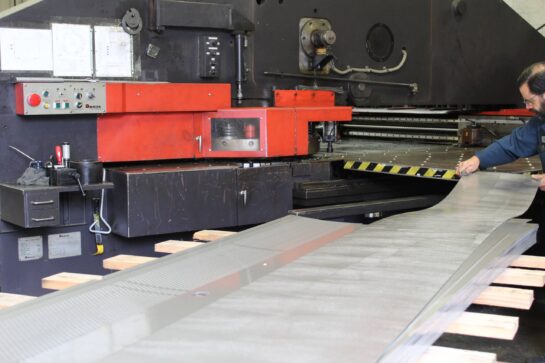

From Start to Finish – Our Production in Action

Learn More in Our Knowledge Base

- Choosing the Right Pattern for Perforated Metal

- Enhancing Safety with Perforated Metal Panels

- How Accuracy Reduces Costs and Waste in Metal Fabrication

- Perforated Metals Handbook

- Perforated Stainless Steel Sheet Metal

- Stainless Steel vs. Carbon Steel

- Stainless Steel vs. Mild Steel

- The Materials Perforating Process

- Turret Punch Press

- Unique Uses for Perforated Metal

Project Specifications

Materials

Capabilities

Equipment

Hole Style

Screen Style

Project Type

Application

Client Type

- Customer: GEM Equipment of Oregon Inc.