How Materials Perforation Works

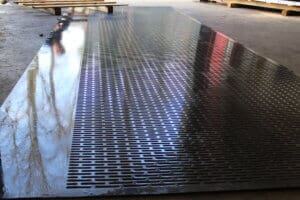

In the heart of Roy Manufacturing’s facility in Portland, Oregon, CNC punch press machines hum with activity, precisely punching holes into a variety of materials, from delicate plastics to robust steel. This remarkable feat of engineering is a testament to innovation and precision. If you’ve ever wondered how materials perforating process works, it is quite the site to behold.

The Digital Blueprint: From CAD to Reality

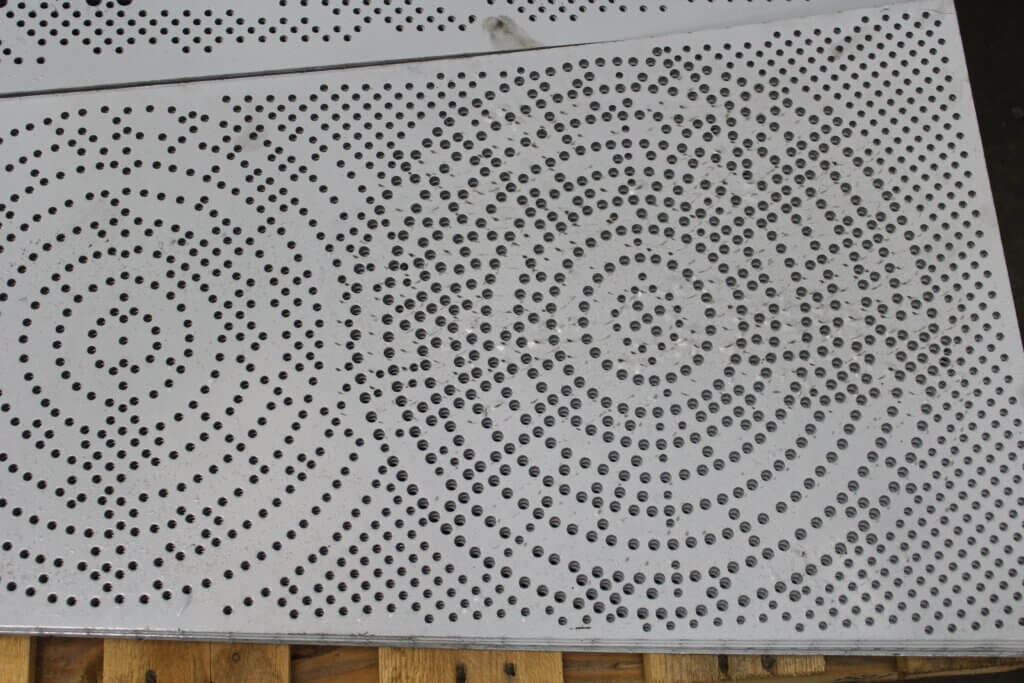

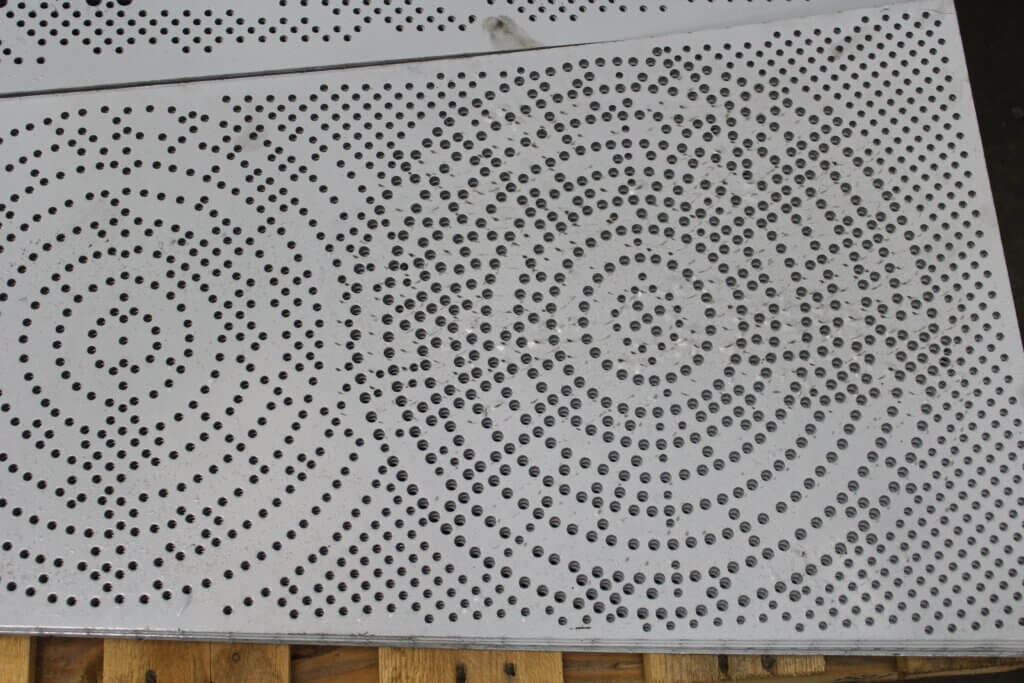

Every screen, architectural element, or component Roy Manufacturing produces begins its journey as a digital blueprint. The process commences with a collaborative effort between our expert team and clients to craft a Computer-Aided Design (CAD) file tailored to each unique project. This CAD file serves as the digital roadmap for the manufacturing process.

The Turret Punch: How the Materials Perforating Process Works

At the heart of Roy Manufacturing’s precision punching capabilities lies the turret punch mechanism. This cutting-edge tool utilizes two rotating wheels, aptly named turrets, working in perfect harmony to craft meticulously designed holes with remarkable precision.

The upper turret boasts the capacity to house up to sixty punch tools, each securely held in holders known as turret keys. Simultaneously, the lower turret accommodates the corresponding dies. The synchronized rotation of these turrets ensures that the correct punch tool and die pair aligns precisely under the striker plate, poised to breathe life into the CAD-defined design.

Once the material is securely clamped onto the table, the operator initiates the process. The material advances under the machine’s meticulous guidance, positioning it accurately beneath the punch press. It’s a dance of precision orchestrated by the machine’s advanced technology.

As the turret wheel rotates, it swiftly selects the appropriate punch tool and matching die, positioning them above and below the material. Unlike the material, which moves forward, backward, and side-to-side beneath the press, the punch tool and die remain stationary, awaiting their cue to execute the design.

The punch press is a powerhouse of precision. It exerts tremendous force as the press and striker unit descend, executing the design by punching the punch tool through the material and into the die. This controlled force results in flawless holes or intricate patterns etched into the material, with a level of precision that is unmatched.

As the press and striker ascend, a lifter swiftly raises the punch tool from the die, preparing it for the next strike. This rapid motion resembles the precise piston action within a vehicle engine, a testament to the meticulous engineering of the CNC punch press. To ensure optimal performance, the operator can adjust the machine’s speed, ensuring smooth operation and impeccable results.

Complex designs often require multiple trips under the punch press. This strategic approach allows for the creation of a second series of holes, with less remaining material in between, ultimately achieving even greater precision in the final product.

Roy Manufacturing’s CNC punch presses represent the pinnacle of precision, efficiency, and craftsmanship in the manufacturing industry. From the digital blueprint to the final punched product, our commitment to innovation and precision shines through, ensuring that we consistently exceed our clients’ expectations. Contact us today to experience the remarkable capabilities of our CNC punch presses and turn your visions into reality.