Roy Manufacturing is Your Source for Premier Perforated Stainless Steel Sheet Metal

Stainless steel, a versatile alloy, is celebrated for its exceptional properties. Composed primarily of iron, chromium, nickel, and other elements, it boasts remarkable corrosion resistance, making it ideal for a wide array of applications. Its resistance to rust and staining, even in harsh environments, renders it a cornerstone in industries such as construction, manufacturing, and healthcare. Stainless steel’s durability and longevity reduce maintenance costs and environmental impact. Its aesthetic appeal graces kitchens, architecture, and consumer goods. Beyond its utilitarian virtues, stainless steel’s enduring popularity is a testament to its enduring elegance and ability to seamlessly blend form and function. Perforated stainless steel sheet metal is an ideal product for many commercial purposes, including industrial design and architecture.

Why choose perforated stainless steel sheet metal?

High-grade perforated stainless steel sheet metal boasts remarkable versatility across multiple applications due to its robustness, resistance to corrosion, and aesthetic allure. The composition of stainless steel encompasses chromium, endowing it with the unique ability to ward off the formation of ferric oxide, a process triggered by oxygen exposure. This distinctive property gives rise to its signature radiance, coupled with its minimal maintenance prerequisites, rendering it the ultimate choice for myriad purposes. Architects, engineers, and designers employ this captivating and enduring metal in a plethora of innovative ways–in both solid sheet and perforated stainless steel formats.

Applications

Stainless steel is a versatile material that can be used in a variety of applications. Here are some of the most common uses for solid and perforated stainless steel:

- Architectural Design: Often used as accent pieces in architectural design. It can be used to create unique patterns and designs that add visual interest to a building’s exterior or interior.

- Filtration: Frequently used in filtration applications due to its ability to allow fluids and gases to pass through while retaining solid particles. This makes it ideal for use in air and water filtration systems.

- Ventilation: Perforated materials work well in ventilation systems to allow air to flow through while preventing debris and other particles from entering.

- Industrial Applications: Commonly used in a variety of industrial applications, including screens, guards, and grates. It is also used in the production of nuts and bolts, aircraft fittings, gears, and bushings.

- Landscaping: Perfect for landscaping applications to create unique garden features, such as trellises and privacy screens.

- Acoustics: Effective in improving acoustics in a space by absorbing sound waves. This makes the material ideal for use in concert halls, recording studios, and other spaces where sound quality is important.

- Lighting: Used by artists and designers to create unique lighting fixtures that cast interesting patterns and shadows.

- Automotive: Valued in the automotive industry for a variety of applications, including grilles, speaker covers, and heat shields.

- Medical: Effective in the medical industry for a variety of applications, including surgical instruments and implants.

- Food Processing: Used in the food processing industry for applications such as strainers and sieves due to its hygienic properties.

Advantages in Industrial Design and Architecture

- Resistant to corrosion: Stainless steel can be used for interior and exterior applications. It won’t rust or warp from wet or typical heat.

- Customizable with different finishes: Our team will work with you to select a finish option that meets your specifications and design needs.

- Sustainable, renewable, and recyclable: Stainless steel is 100% recyclable and doesn’t degrade, so scrap metal can be reused rather than ending up in a landfill.

- Durable: Your perforated stainless steel sheet metal product will stand the test of time.

Roy Manufacturing – A Legacy of Excellence

Established 65 years ago by Roy O. Young, Roy Manufacturing has upheld a tradition of crafting quality perforated products from our Portland facilities. Our dedication to superior service and unparalleled workmanship remains steadfast, even as ownership has evolved over time.

Our Philosophy: On Spec and On Time

Roy Manufacturing operates with a clear philosophy: delivering exceptional customer service and industry-leading expertise in materials perforation production. Our reputation thrives on delivering high-quality products on time and to specification.

Material Mastery

We work with an array of materials, including stainless steel, aluminum, brass, copper, and more, showcasing our versatility and adaptability.

Applications Across Industries

Roy Manufacturing’s perforated materials find homes in various industries, including architecture, automotive, agriculture, and filtration systems.

Precision in Production

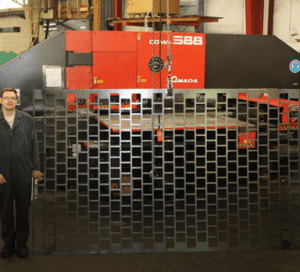

Equipped with eight CNC-controlled turret punch presses ranging from 30-ton to 50-ton punching capacity, Roy Manufacturing operates from four buildings, supported by pre-production and post-production equipment.

Your Custom Solution

Our expertise and cutting-edge equipment enable us to handle custom perforation projects tailored precisely to your requirements.

Whether it’s enhancing aesthetics, improving functionality, or solving intricate design challenges, Roy Manufacturing’s aluminum perforated sheet products stand as your reliable partner in achieving exceptional results. Contact us today to explore the possibilities!