Redd Zone, a leading advocate for advancements in fisheries technology, is revolutionizing fish culture practices to enhance the quality of salmon and trout while minimizing the environmental footprint. With a focus on innovative solutions and sustainable approaches, Redd Zone has garnered recognition for their commitment to fish health, cost reduction, and reduced use of harsh chemicals. Roy Manufacturing is proud to be selected to manufacture components for two of their systems: the “Portable Egg Eyeing Station” and the “Best Fry Swim Out” incubator.

Roy Manufacturing produces an average of 1300 pieces for Redd Zone annually to fulfill ongoing weekly orders, comprised of:

- 12” x 16” sheets, round perf 3/32” diameter, .291” stagger

- 17” x 20¾” sheets, round perf 3/32” diameter, .291” stagger

- 23¾” x 36” sheets, obround perf 3/16” x 3/4”, side staggered

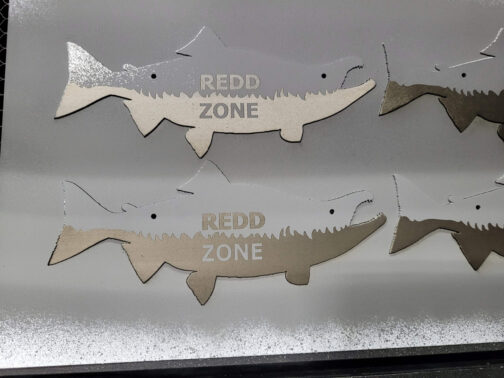

Portable Egg Eyeing Station

Tod Jones, CEO of Redd Zone, has been instrumental in pioneering the non-profit hatchery movement and managing a groundbreaking project that produced over 100 million salmon fry annually. His latest invention, the “Portable Egg Eyeing Station,” is currently undergoing beta testing and promises to revolutionize the process of eyeing up salmon and trout eggs.

This innovative system provides an oxygen-rich environment for operators to evaluate and manage salmon or trout eggs of various species. The station incorporates temperature modulation and chilling capabilities using recycled water, enabling precise control over egg development. Roy Manufacturing produces the fish plates for each unit. The pieces are laser cut, and the logo and design are etched into each fish plate by Roy Manufacturing’s sister company, Profile Laser.

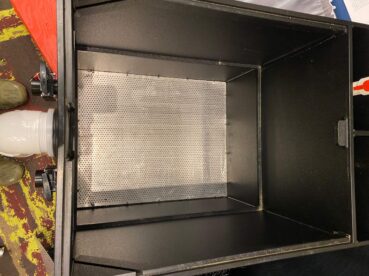

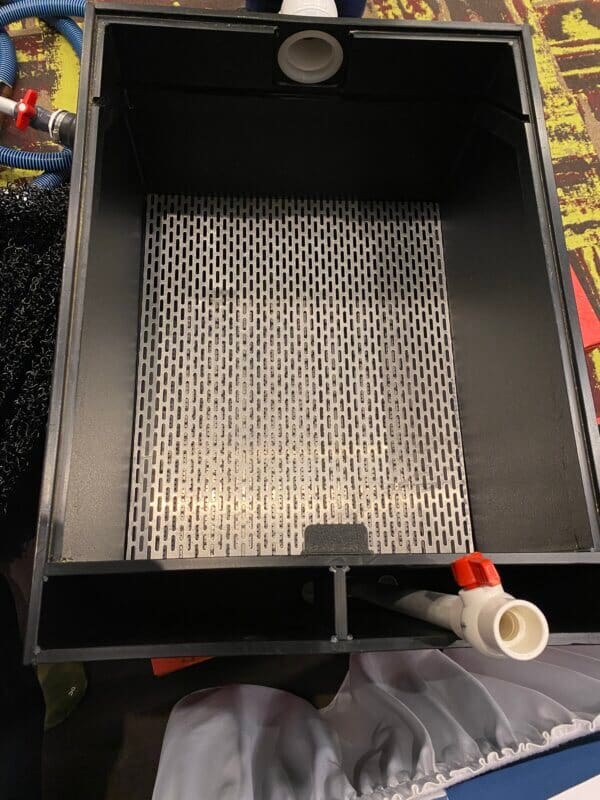

Best Fry Swim Out Incubator

In their commitment to producing the highest quality salmon and trout fry, Redd Zone offers “Best Fry Swim Out” incubators. These cutting-edge incubators outperform traditional vertical trays and trough incubators, resulting in heavier and healthier emergent fry. These incubators’ water conservation and space utilization are unparalleled, while their seamless integration into existing infrastructure minimizes the need for plumbing alterations.

The incorporation of isolation inserts allows for the separation of different lots of eggs, ensuring optimal tracking and management. Moreover, Redd Zone’s recent introduction of new fry media further streamlines cleanup processes and facilitates quicker fry outmigration. Roy Manufacturing produces the metal screens for installation inside the units.

How can Roy Manufacturing help your business achieve success?

Contact us today to learn more about our equipment and technologies that we can use to fabricate parts or large-scale products for your operation’s needs. We’re committed to quick turnarounds, superior service, and high-quality work that meets your specifications. Contact us today for a free quote.

Project Specifications

Materials

Capabilities

Equipment

- Accushear 12' x 1/4" Metal Shear

- Amada Octo 334 Turret Punch Press

- CM1690 Redsail CO2 Engraving Laser

- CM1690 Redsail CO2 Etching Laser

- TRUMPF 2030 Fiber Laser

- TRUMPF 3030 Fiber Laser

Hole Style

Screen Style

Project Type

Client Type

- Customer: Redd Zone