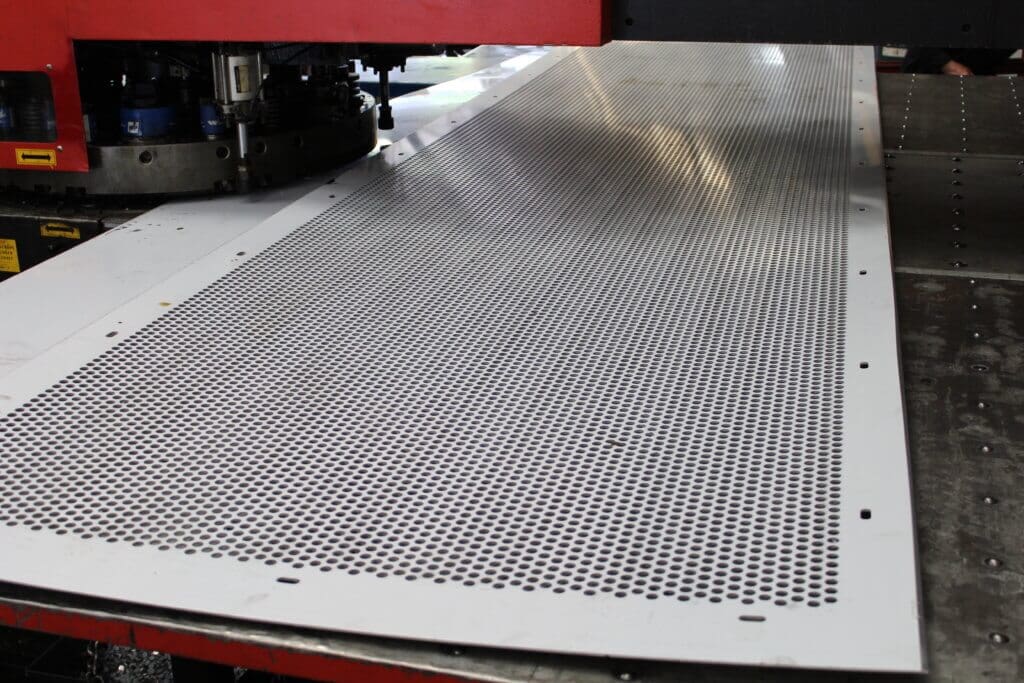

Perforated Aluminum Sheet Products - Solutions for Aesthetic and Functional Design

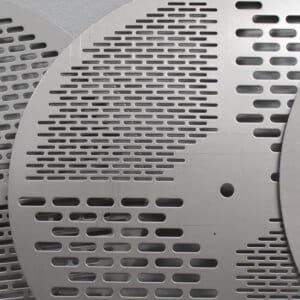

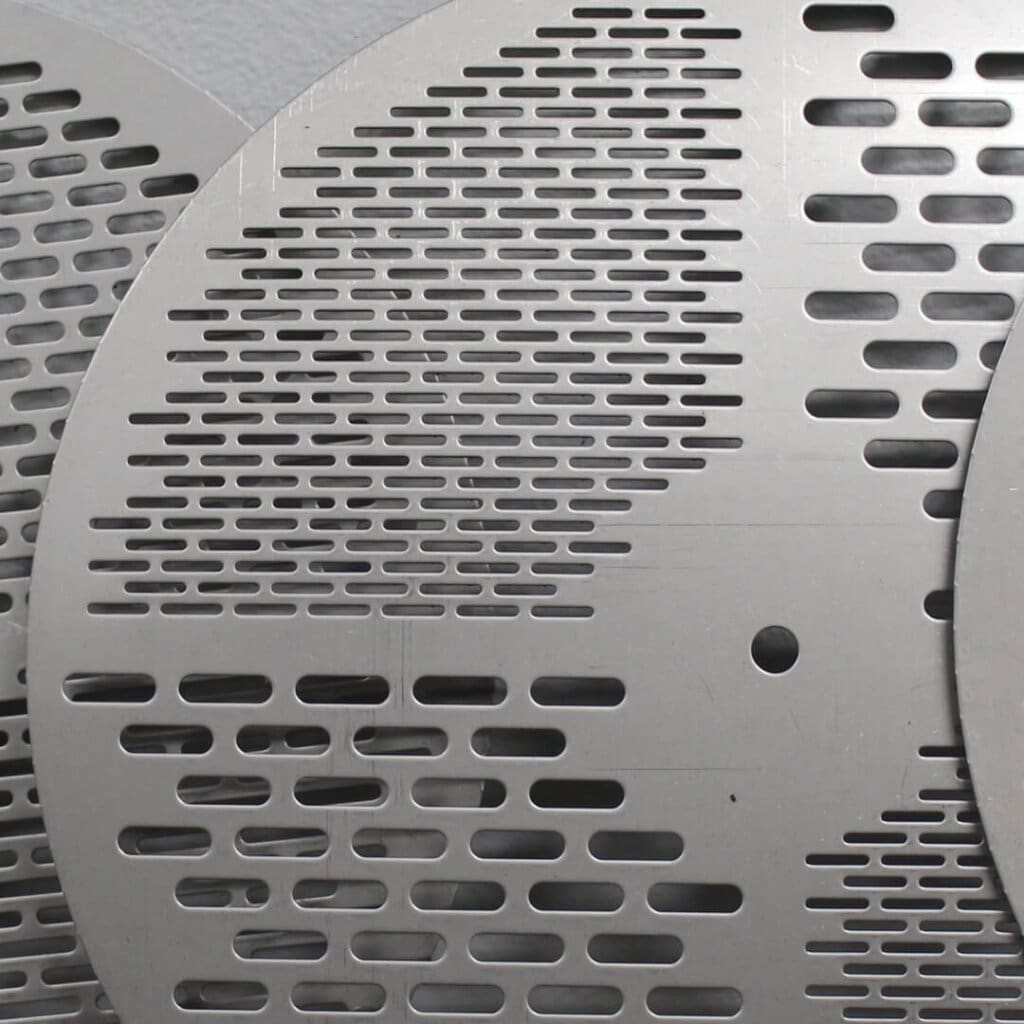

Aluminum perforated sheet products are specialized metal sheets punctured with a strategic pattern of holes or perforations. These perforations come in various shapes and sizes, including round, square, rectangular, and decorative patterns. Aluminum is the material of choice for perforated sheets due to its trifecta of advantages: lightweight construction, resistance to corrosion, and inherent malleability.

Why choose aluminum perforated sheet products?

As a lightweight metal with a low density, aluminum possesses a remarkable strength-to-weight ratio as a direct result of its crystal structure. This atomic arrangement contributes to the material’s malleability, allowing it to be easily formed into intricate patterns of perforations without sacrificing structural integrity.

Moreover, aluminum’s natural oxide layer provides inherent corrosion resistance, making it a durable choice for both indoor and outdoor applications.

The science behind aluminum, from its atomic structure to its unique metallurgical properties, synergizes with precision manufacturing techniques to create perforated sheets that are not only aesthetically versatile but also functionally superior. This scientific foundation underscores why aluminum perforated sheets are a trusted solution across industries, offering the perfect blend of lightweight durability, corrosion resistance, and tailored design possibilities.

Applications

Aluminum perforated sheets are a smart choice for a range of applications that blend functionality with durability:

1. Lightweight Strength: Aluminum’s lightweight nature doesn’t compromise its strength. Perforated aluminum sheets maintain structural integrity while remaining easy to handle and install, making them suitable for projects where weight is a consideration.

2. Practical Versatility: The diverse perforation patterns, whether circular, square, or custom-designed, offer practical benefits. These sheets enable controlled airflow, making them apt for ventilation systems and equipment enclosures.

3. Controlled Lighting: The holes in perforated sheets allow controlled light diffusion, making them useful for light fixtures or architectural elements that require even illumination without glare.

4. Enhanced Acoustics: In workspaces where sound control matters, perforated aluminum panels can be employed to absorb sound waves, minimizing echoes and enhancing the overall acoustic environment.

5. Privacy Solutions: For areas that necessitate visibility without full exposure, perforated sheets act as effective privacy screens, allowing airflow and partial sightlines while maintaining a sense of enclosure.

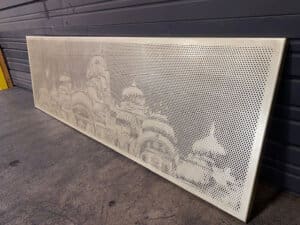

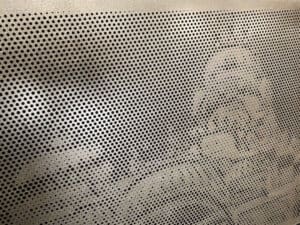

6. Design and Aesthetics: Perforated sheets can be integrated seamlessly into architectural designs, creating visually appealing facades, partitions, and decorative elements that combine form and function.

7. Customization for Efficiency: Aluminum perforated sheets can be customized to align with specific project requirements. Custom hole patterns, sizes, and sheet dimensions ensure optimal results for your application.

8. Durability in Diverse Environments: Aluminum’s corrosion resistance makes perforated sheets suitable for both indoor and outdoor applications, even in challenging environments.

Advantages in Industrial Design and Architecture

Manufacturers and designers use perforated metals for many applications because of the advantages they provide over other materials:

- Enhanced Aesthetics: Perforated metals introduce visual intrigue and texture to structures or products, becoming distinctive design elements.

- Functionality: The presence of holes facilitates airflow, sound transmission control, light diffusion, and visibility. This renders perforated metals fitting for ventilation systems, acoustic panels, decorative screens, and façade cladding.

- Structural Integrity: Despite the presence of holes, perforated metals maintain their structural strength, ensuring durability in various environmental conditions.

- Customization: Perforated metals can be tailored to precise design demands, offering flexibility in hole size, shape, spacing, and overall sheet dimensions.

Roy Manufacturing – A Legacy of Excellence

Roy Manufacturing – A Legacy of Excellence

Established 65 years ago by Roy O. Young, Roy Manufacturing has upheld a tradition of crafting quality perforated products from our Portland facilities. Our dedication to superior service and unparalleled workmanship remains steadfast, even as ownership has evolved over time.

Our Philosophy: On Spec and On Time

Roy Manufacturing operates with a clear philosophy: delivering exceptional customer service and industry-leading expertise in materials perforation production. Our reputation thrives on delivering high-quality products on time and to specification.

Material Mastery

We work with an array of materials, including stainless steel, aluminum, brass, copper, and more, showcasing our versatility and adaptability.

Applications Across Industries

Roy Manufacturing’s perforated materials find homes in various industries, including architecture, automotive, agriculture, and filtration systems.

Precision in Production

Equipped with eight CNC-controlled turret punch presses ranging from 30-ton to 50-ton punching capacity, Roy Manufacturing operates from four buildings, supported by pre-production and post-production equipment.

Your Custom Solution

Our expertise and cutting-edge equipment enable us to handle custom perforation projects tailored precisely to your requirements.

Whether it’s enhancing aesthetics, improving functionality, or solving intricate design challenges, Roy Manufacturing’s aluminum perforated sheet products stand as your reliable partner in achieving exceptional results. Contact us today to explore the possibilities!

Roy Manufacturing – A Legacy of Excellence

Roy Manufacturing – A Legacy of Excellence