Parking garages are something that most people don’t give much thought to. Yet these pieces of urban infrastructure play a large role in how people experience cities, workplaces, hospitals, and mixed-use developments. As vehicles have evolved and building codes have become more rigorous, the expectations for parking structures have dramatically shifted. Effective parking garage ventilation and occupant safety aren’t just regulatory requirements anymore – they’re essential design priorities. Perforated metal is one material that consistently delivers on both of these goals.

How Does Perforated Metal Improve Parking Garage Ventilation and Safety?

1. Natural Ventilation Without Compromise

Vehicle exhaust is one of the primary challenges in parking garage design. Carbon monoxide and other harmful emissions can accumulate quickly, especially in enclosed or multi-level structures. Mechanical ventilation systems can help, but they come with higher energy costs, ongoing maintenance requirements, and vulnerability during power outages.

Perforated metal, on the other hand, allows designers to take advantage of natural airflow. Strategically placed perforated panels let fresh air circulate freely while exhaust gases dissipate efficiently. This type of passive ventilation approach can significantly reduce the need to rely on mechanical systems, improving air quality while lowering long-term operating costs.

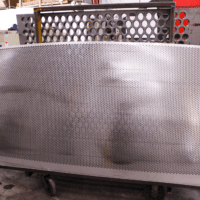

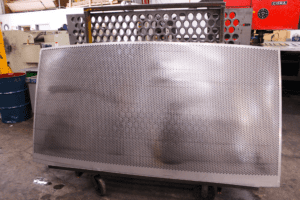

At Roy Manufacturing, we’ve seen how properly specified perforation patterns and open-area percentages can be engineered to meet ventilation code requirements without sacrificing integrity or aesthetics.

2. Enhanced Safety for Drivers and Pedestrians

While perforated metal can help improve parking garage ventilation, that’s only one aspect of safety. Visibility and situational awareness are just as important in parking environments where you commonly run into tight turns, pedestrian traffic, and varying light conditions.

While perforated metal can help improve parking garage ventilation, that’s only one aspect of safety. Visibility and situational awareness are just as important in parking environments where you commonly run into tight turns, pedestrian traffic, and varying light conditions.

Perforated metal panels work to improve sightlines by allowing light and visibility through garage facades and internal partitions. This allows drivers to see approaching vehicles, cyclists, or pedestrians more easily, reducing the risk of collisions. From the pedestrian perspective, improved sightlines create a greater sense of awareness and comfort, which is an important factor in perceived safety.

Perforated metal also contributes to fire safety. In the event of a fire, open-area designs help heat and smoke to vent more quickly, improving the conditions for evacuation and emergency response.

3. Durability That Supports Long-Term Safety

Parking garages are harsh environments. Exposure to moisture, road salt, exhaust fumes, and temperature fluctuations can degrade many of the building materials over time. Corrosion and structural failure aren’t just maintenance concerns – they’re safety risks.

When manufactured with appropriate alloys and finishes, perforated metal panels offer exceptional durability. Galvanized, aluminum, or stainless steel options resist corrosion and maintain performance for decades. This longevity ensures that ventilation openings remain unobstructed and structural components retain their integrity long after installation.

At Roy Manufacturing, we produce perforated solutions with real-world conditions in mind. Our products help owners avoid costly repairs while maintaining consistent safety performance.

4. Aesthetic Transparency That Encourages Use

Safety is not only physical, but psychological. Dark, enclosed garages can feel intimidating, which can discourage use and increase concerns about personal safety. Perforated metal helps circumvent this by introducing daylight into parking structures to create bright, welcoming environments.

Architects are increasingly using perforated metal to balance openness with visual screening. The result is a parking garage facade that allows airflow and light to improve ventilation and safety while still obscuring vehicles from street view. This transparency helps to make the structure feel less isolated and more secure.

5. Supporting Sustainable and Code-Compliant Design

Modern building codes and sustainability standards favor designs that reduce energy consumption and improve indoor environmental quality. Perforated metal supports both of these objectives by allowing for natural ventilation and daylight.

In many cases, parking garages designed with perforated facades can qualify as “open parking structures”. This simplifies compliance with ventilation requirements and reduces the need for energy-intensive systems.

Building Safer, Smarter Structures with Roy Manufacturing

Perforated metal supports smarter parking garage design by addressing ventilation and safety challenges at their source, rather than relying on mechanical fixes after the fact. At Roy Manufacturing, we partner with architects, engineers, and developers to create safe, efficient solutions with long-term value. Contact us today to see how we can help your project meet modern expectations while preparing for the ventilation and safety demands of tomorrow.