How Accuracy Reduces Costs and Waste in Metal Fabrication

In metal manufacturing, precision is more than a measure of quality—it is a driver of efficiency and profitability. When perforation is performed accurately, projects stay on schedule, material waste is reduced, and costs remain predictable. Precision in perforation influences every stage of production, from raw material usage to delivery timelines. At Roy Manufacturing, we prioritize accuracy. Here’s why it’s so important to us:

Avoiding Rework and Production Delays

Accuracy saves money by preventing rework. If perforated sheets are even slightly misaligned, they may fail to meet design specifications or compromise the structural integrity of the final product. This can force costly corrections, redesigns, or scrapped components.

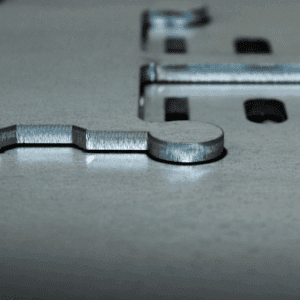

High-quality perforation systems maintain consistent hole placement and spacing across entire sheets. By producing patterns that match the intended design exactly, they eliminate the ripple effects of misalignment: halted production lines, wasted labor, and delivery delays. With precision from the start, projects move forward smoothly and deadlines are met without costly interruptions.

Maximizing Material Savings

Material is one of the largest expenses in metalworking, making optimization essential. Accurate perforation allows sheets to be used to their fullest potential. When hole placement is inconsistent, manufacturers must leave extra margins to compensate for potential defects, which reduces yield and drives up material costs.

By contrast, precision perforation ensures every pattern is centered and consistent, allowing parts to be laid out efficiently across the sheet. This nesting process minimizes offcuts and maximizes usable space, directly reducing the cost of raw materials. Even small percentage gains in material yield add up to significant savings over large production runs.

Reducing Scrap and Supporting Sustainability

Minimizing scrap benefits the bottom line and supports sustainability goals. Every pound of excess metal that ends up in recycling bins or landfills requires additional energy to transport and process. Preventing waste at the source is more responsible and cost-effective.

Precision perforation helps achieve this by producing only the required parts with minimal excess. Less scrap means lower energy consumption across the supply chain and a smaller carbon footprint for manufacturing operations. For many businesses, this alignment of efficiency and sustainability helps meet customer expectations and maintain brand reputation.

Choosing the Right Perforation Partner

The benefits of accuracy in perforation depend on working with the right partner. Roy Manufacturing will:

- Invest in advanced perforation equipment.

- Use rigorous inspections to confirm pattern consistency.

- Calibrate machines regularly to maintain precision.

- Train technicians to operate and monitor systems effectively.

Our commitment to accuracy ensures perforated sheets meet specifications the first time, with minimal waste or rework. By choosing Roy Manufacturing, you can be assured you’re working with a company that prioritizes precision, helps control costs, respects your timelines, and maximizes material use. Contact us today to learn more!