In the world of industrial processing, the quest for efficiency and precision has driven continuous innovation. Roy Manufacturing is proud to manufacture a game-changing solution for its clients in the form of polyurethane sorting screens. These screens have redefined the process of material classification, setting new standards for durability, performance, and effectiveness across diverse industries.

The Advantages of Polyurethane Sorting Screens

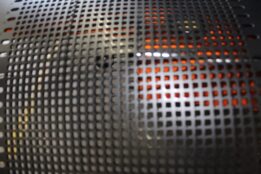

Roy Manufacturing’s polyurethane sorting screens epitomize the fusion of cutting-edge technology and practical utility. Unlike conventional metal or wire mesh screens, these screens leverage the distinctive properties of polyurethane to address specific material-screen interaction dynamics. The ability of certain materials to glide effortlessly across polyurethane, a trait attributed to its unique chemical composition, dictates the suitability of these screens in various applications.

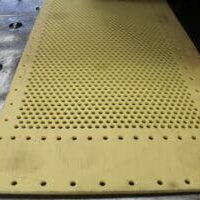

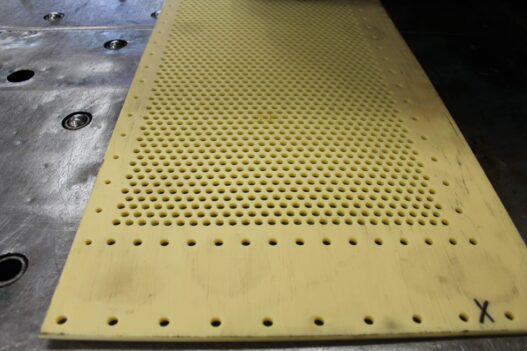

Roy Manufacturing’s polyurethane sorting screens come in two different colors – black and off-white. This seemingly aesthetic differentiation, however, serves a functional purpose. The color variation is a direct result of the type of polyurethane employed in the manufacturing process. Each color is tailored to a specific set of properties that not only ensure optimal performance but also enhance the longevity of the polyurethane material, making it resistant to the challenges posed by the materials being processed. Black, for example, is used specifically for wood processing work.

Precision Redefined

Polyurethane sorting screens are optimal solutions for many clients due to the abundant benefits they have for processing purposes.

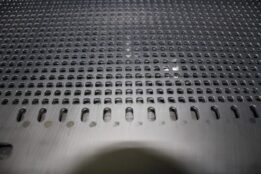

The longevity of Polyurethane Sorting Screens is a standout feature. Their durability outshines traditional woven wire screens, translating into substantial cost savings on operational and labor fronts. The flexible nature of polyurethane screens allows them to flex and resist clogging, a common issue in screening applications. Additionally, their lightweight design contributes to long-term energy efficiency.

The versatility of polyurethane screens truly shines in both wet and dry applications. Whether confronted with the challenges of wet screening or the intricacies of dry classification, these screens adapt seamlessly, showcasing their superior material flexibility and resistance.

Other benefits include:

- Abrasion Resistance: The exceptional abrasion resistance of polyurethane screens ensures longevity and consistent performance in high-wear applications.

- Corrosion-Free: Unlike traditional screens, polyurethane screens are immune to corrosion, reducing maintenance and replacement costs.

- Noise Reduction: These screens operate with significantly reduced noise levels, contributing to a more comfortable working environment.

- Flawless Precision: Polyurethane sorting screens deliver unwavering precision in material classification, minimizing mixing fractures and cracking during vibration.

- Repairability: The repairability of polyurethane panels prolongs their lifespan.

- Customizability: The potential for exchanging individual modules and ease of installation underscore the adaptability of these screens.

Choose Roy Manufacturing for your production equipment.

Roy Manufacturing’s polyurethane sorting screens aren’t just products; they signify a paradigm shift in how industries approach sorting and classification challenges. With unparalleled durability, precision, and adaptability, these screens are set to define a new era in industrial processing. As companies seek more efficient and sustainable solutions, Roy Manufacturing’s polyurethane sorting screens stand as a testament to the power of innovation in reshaping industries for the better.

Learn More in Our Knowledge Base