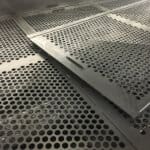

Custom Perforating Solutions

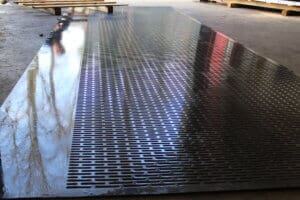

Perforated metals and materials are versatile for a wide range of applications in various industries. In the simplest of terms, custom perforating solutions are punched with a pattern of holes or slots according to the customer’s specifications to meet their unique requirements. Our perforated metals and materials provide solutions for manufacturing, architectural, agricultural, industrial, and home applications–just to name a few! Explore the benefits of custom perforating and how it can be used in different industries.

What is Custom Perforating?

We know no two custom needs are identical, so our team specializes in creating custom solutions to your specs and standards. Our machinery uses computerized files to accurately punch a pattern of holes or slots in a metal sheet to meet your specific requirements. These perforations can be customized in terms of size, shape, and pattern to suit different applications.

Custom perforating can be done on a wide range of materials, including stainless steel, aluminum, brass, copper, galvanized steel, and polyurethane.

Use our Perforated Material Open Area Calculator

Not sure what the final product will look like? Check out our user-friendly tool for perforated sheet calculations. By simply entering the hole dimensions and selecting the desired pattern, our open area calculator will provide you with the percentage of open area for your perforated metal project

Benefits of Custom Perforating Solutions

Our customers choose custom perforated materials to solve a variety of challenges because of the many benefits they provide.

Improved Aesthetics: Custom perforated metal and materials can be used to create unique and attractive designs for architectural and decorative applications. The perforations can be customized to create intricate patterns that add visual interest to buildings, facades, railings, and sunscreens.

Enhanced Functionality: Our solutions can be used to improve the functionality of products and equipment. For example, perforated metal sheets can be used as filters, screens, and grilles to control the flow of air, water, and other fluids.

Increased Durability: Perforated metal sheets are more durable than other materials, such as plastic or wood. They are resistant to corrosion, rust, and wear and tear, making them ideal for use in harsh environments. However, we also perforate other durable materials such as polyurethane. Contact our team to learn more about all the types of materials available.

Improved Sound Absorption: Perforated metal sheets can be used to reduce noise levels in buildings and other structures. The perforations in the metal sheet help to absorb sound waves, making them ideal for use in acoustic paneling and other soundproofing applications.

Common Applications for Our Products

Custom perforating can be used in various industries. Here is a small sample of the types of businesses and consumers we serve.

Manufacturing

Customers choose Roy Manufacturing for perforated metals and materials that will fit equipment precisely for various manufacturing needs. For example, perforated metal sheets can be used to create filters, screens, and grilles for industrial equipment. They can also be used to create parts for machinery and equipment.

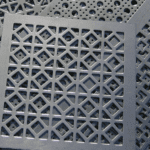

Architectural

Custom perforated metal sheets are often used in architectural applications to create unique and attractive designs. For example, perforated metal sheets can be used to create facades, railings, sunscreens, and other decorative elements for buildings. They can also be used to create acoustic paneling and other soundproofing applications. See how our decorative screens provide functional shade and aesthetic beauty to Spokane Community College.

Agricultural

Custom perforated metal sheets can be used in agricultural applications to create products that require precise perforations. For example, perforated metal sheets can be used to create screens and filters for irrigation systems. They can also be used to create parts for farm machinery and equipment. Learn more about Roy’s vibratory screens used in agricultural collection and processing facilities.

Industrial

Industrial

Custom perforated metal sheets can be used in industrial applications to create products that require precise perforations. For example, perforated metal sheets can be used to create screens, filters, and grilles for industrial equipment. They can also be used to create parts for machinery and equipment.

In the Home

Our products are just for commercial purposes. Perforated materials make functional and aesthetically pleasing solutions for our customers’ homes, too. For example, perforated metal sheets can be used to create decorative elements for furniture, lighting fixtures, and other home accessories. They can also be used to create acoustic paneling and other soundproofing applications. Check out these custom firepits we manufactured for one of our customers.

Choose Roy Manufacturing for high-quality custom solutions.

If you are looking for a versatile and durable material for your next project, contact our team at Roy Manufacturing. Whether your project is large or small, you can rest assured you’ll receive a high-quality product that fits your specifications perfectly. Contact us today, and let’s discuss bringing your plans to reality.

Industrial

Industrial