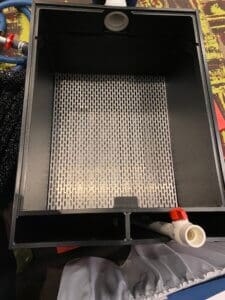

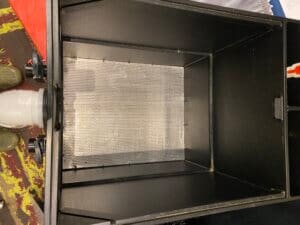

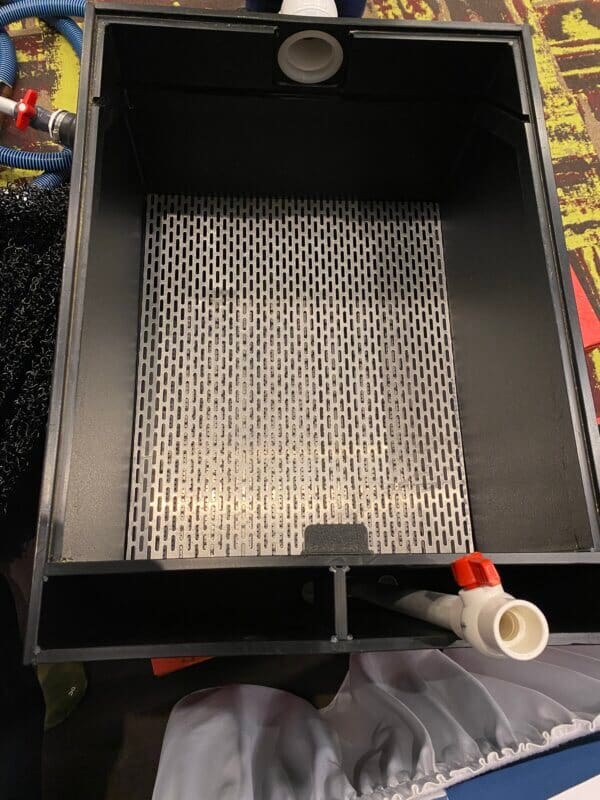

Custom Perforated Fish Screens

As a leading manufacturer of perforated metal products, we specialize in providing high-quality fish screens that serve as positive barrier screens, effectively protecting aquatic organisms during water diversion. Fish screens are a critical element of aquatic life protection, debris management, and sediment control.

Fish Screens 101

The main purpose of a fish screen is to create a physical barrier that keeps fish and fry (young fish) on one side while preventing them from getting to the other side. They separate bigger fish from smaller fish. This can be important in certain situations where different sizes of fish need to be kept apart for specific reasons.

One of the primary reasons for using fish screens is to make sure fish do not escape from their designated areas. Fish may try to swim away from their intended locations, and fish screens act as a protective boundary to keep them contained. Additionally, fish screens serve to keep fish away from mechanical devices or equipment that could be harmful to them.

Fish screens are particularly valuable in areas where fish are being cultivated, especially during the egg and fry stages. The screens help to maintain a controlled environment, ensuring that the fish stay where they are intended to be. This is crucial for managing the fish populations and facilitating their growth and development.

Fish Protection: Preserving Aquatic Ecosystems

It is essential to consider the well-being of fish beyond mere exclusion. Screens should be designed to prevent fish impingement on the screen surface caused by flow passing through the screen. Impingement can lead to breathing impairment, scale loss, bruising, increased stress levels, and ultimately fish mortality or injury. Our fish screens are meticulously engineered to minimize the risk of impingement and ensure the safety of the fish.

Debris Management: Keeping Water Diversion Clean

In addition to fish protection, fish screens play a crucial role in managing debris and sediment during water diversion. Debris load can vary depending on factors like season, screen location, and debris type. Woody debris and domestic refuse tend to accumulate during high-flow events, while aquatic plant load is often highest in late summer and early fall.

To effectively manage debris, fish screens can employ both active and passive cleaning methods. Active cleaning methods rely on mechanical cleaning, while passive methods capitalize on screen design and flow sweeping to limit debris impingement. At Roy Manufacturing, we work closely with our clients to assess their specific debris management requirements and recommend the most suitable approach.

Our general approaches to debris management include:

- Excluding debris: By diverting the water while leaving the debris in the stream or lake, active or passive debris management methods can be used effectively.

- Passing debris downstream: This approach involves utilizing rotating screens designed to pass impinged debris over the top of the screen, allowing the screened water to carry debris away.

- Removing debris for disposal: In cases where debris removal is necessary, rotating screens equipped with a debris sluice or conveyor can be employed to collect and dispose of the debris on-site.

The choice of debris management method depends on the specific project requirements and circumstances, and our team at Roy Manufacturing can guide you in making an informed decision.

Sediment Management: Controlling Suspended and Bed Sediments

Water diversion can sometimes pick up and carry small pieces of dirt and sand, or “sediment.” This sediment can be of two types: larger, heavier pieces that roll along the bottom (bed load) and smaller, lighter pieces that float in the water (suspended sediment). Fish screens are specially designed barriers that can help control and manage this sediment. They can prevent both the larger, rolling sediments like sands and gravels, as well as the smaller, floating sediments like fine sand, silt, and clay, from getting into places where they shouldn’t be. By using well-designed fish screens, we can ensure that the water stays cleaner and healthier for the fish and other aquatic life.

Fish screens can be designed to exclude a significant portion of bed load by selecting the appropriate screen type, ensuring a strong sweeping flow that transports bed load away from the screen, and utilizing proper screen mesh sizing.

It is worth noting that the amount of sediment generally increases with stream flow. Roy Manufacturing’s fish screens are designed to mitigate sediment-related issues. This is especially helpful when the water coming from ditches has a lot of suspended sediment (tiny floating particles). The fish screens help trap some of the suspended sediment and make the water cleaner downstream.

Why Choose Roy Manufacturing?

Quality Craftsmanship: With a commitment to excellence, we pride ourselves on delivering custom perforated metal panels of the highest quality. Each panel is meticulously crafted using premium materials and cutting-edge manufacturing techniques to ensure durability and precision.

Collaborative Approach: We believe in the power of collaboration. Our team works closely with you throughout the entire process, from design conception to final installation, ensuring that your vision is fully realized and your expectations are exceeded.

Customization and Flexibility: At Roy Manufacturing, we understand that customization is key. We offer a wide range of perforation patterns, metal types, finishes, and panel sizes to suit your specific project requirements. Our team is dedicated to bringing your unique ideas to life.

Timely Delivery: We value your time and understand the importance of meeting project deadlines. Our streamlined production process allows us to deliver custom perforated metal panels within agreed-upon timelines without compromising on quality.

Contact Us Today for Custom Perforated Metal Panels

Are you searching for high-quality perforated metal production from a reliable manufacturer? Contact Roy Manufacturing today to discuss your project requirements. Our team of experts is here to guide you through the design process, provide personalized recommendations, and provide a detailed quote tailored to your needs.

With Roy Manufacturing, you can trust your project is in capable hands. We have a proven track record of successful installations and satisfied clients across various industries. Our dedication to quality, craftsmanship, and customer satisfaction sets us apart as a leader in the perforated materials industry.