Enhancing Filtration Efficiency with Perforated Copper

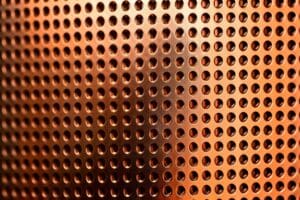

In the world of air filtration, the pursuit of efficiency and durability has led to the exploration of various materials. Among these, perforated copper stands out as a versatile and highly effective component, offering a range of benefits when used in air filters and other filtration systems. Its unique properties make it an exceptional choice for industries where optimal air quality is paramount. Roy Manufacturing can custom cut perforated copper for filtration systems to meet your project specifications.

Why Use Perforated Copper for Filtration Systems:

Copper, revered for its conductivity and malleability, undergoes a perforation process where precise, strategically placed holes are created. These perforations, often in the form of regular patterns, allow for the passage of air while efficiently trapping particulate matter.

Benefits of Perforated Copper in Air Filtration Systems:

1. Exceptional Durability:

Copper, known for its robustness, resists corrosion and deterioration, making it an ideal choice for environments with varying temperatures and high humidity. Its durability ensures a longer lifespan for the filters, reducing the frequency of replacements and maintenance.

2. Superior Filtration Properties:

The intricate design of perforated copper allows for precise control over the size and distribution of the holes. This precision enables effective filtration by trapping particles of varying sizes, including fine particulate matter and even microorganisms, contributing to cleaner air quality.

3. Antimicrobial Properties:

Copper is naturally antimicrobial, exhibiting the ability to eliminate a broad spectrum of harmful microbes. This innate property is a game-changer in environments where maintaining high levels of hygiene is critical, such as in healthcare facilities and cleanroom environments.

4. Enhanced Airflow:

The strategic arrangement of perforations in copper enables efficient airflow while maintaining effective filtration. This balance is crucial in maintaining optimal air quality without compromising on airflow, ensuring that ventilation systems perform at their best.

5. Environmentally Friendly:

Copper is a highly recyclable material, aligning with sustainability goals. Its long-lasting nature reduces the need for frequent replacements, thus decreasing waste and environmental impact.

6. Thermal Conductivity:

Copper’s excellent thermal conductivity makes it an ideal choice when temperature regulation is crucial. It helps maintain consistent airflow and temperature, a significant advantage in industrial settings.

Filtration Applications in Various Industries:

1. HVAC Systems:

Perforated copper filters significantly improve the performance of heating, ventilation, and air conditioning systems. The efficient filtration and durability make them an excellent choice in these systems, ensuring cleaner air circulation.

2. Biomedical and Pharmaceutical Industries:

In these highly regulated industries, maintaining sterile environments is paramount. Perforated copper filters aid in providing clean and microbe-free air, crucial for laboratories and production facilities.

3. Data Centers:

Data centers must ensure a dust-free and clean environment to prevent hardware damage. Perforated copper filters help maintain optimal air quality, thus supporting the seamless functioning of these facilities.

4. Automotive and Aerospace:

Perforated copper filters are used in these industries to maintain air quality in cabins, ensuring occupants’ health and safety while safeguarding sensitive equipment from contamination.

Choose Roy Manufacturing for your perforated copper needs.

The use of perforated copper in air filtration systems represents a significant leap forward in the quest for cleaner and healthier air. Its unique combination of durability, superior filtration properties, antimicrobial characteristics, and environmental sustainability make it a standout choice for various industries. As technology and innovation continue to evolve, the integration of perforated copper in filtration systems is set to redefine standards, ensuring better air quality and improved efficiency.

The remarkable properties of perforated copper make it a compelling solution, setting new benchmarks in air filtration technology and highlighting its invaluable contribution to healthier living and industrial efficiency. Contact us today for a free quote and learn how easy it is to obtain custom perforated metals and materials for your project.

Roy Mfg Projects