Revolutionizing Efficiency: Mastering Precision with Innovative Rock Sifting Screens

Companies across a wide range of industries rely on precision rock sifting screens as part of their operations. We’re proud to work closely with our clients to produce custom-designed screens that perfectly fit their demands to make their processes more efficient and accurate.

Understanding Rock Sifting Screens:

Understanding Rock Sifting Screens:

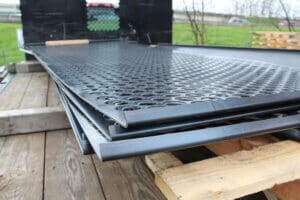

Rock sifting screens, often referred to as rock separators or sifters, are sophisticated tools meticulously designed to address the challenges of sorting and grading various sizes of rocks, minerals, and aggregates with unparalleled precision. These screens incorporate an ingenious combination of engineering and perforated materials to facilitate efficient separation, eliminating the need for labor-intensive manual processes.

At Roy Manufacturing, we recognize the significance of efficient rock separation, and our rock sifting screens stand as a testament to our commitment to innovation and excellence. You’ll find our commitment to quality in every element of their structure: from carefully selected materials perforated with precision to the final, robust framework that optimizes the separation process.

Importance of Precision Sifting:

Construction, mining, landscaping, and agriculture industries all rely on the accurate separation of materials to achieve optimal outcomes. Rock sifting screens are pivotal tools in these sectors, allowing for the extraction of rocks, minerals, and aggregates of desired sizes. The value of precision sifting extends beyond merely obtaining the right particle sizes; it significantly impacts the quality of end products and reduces wastage.

Our perforated materials have been meticulously engineered to deliver superior precision in the separation process. The intricately designed perforation patterns ensure that the right-sized particles pass through, while larger rocks are efficiently sorted out. This precision minimizes the risk of contamination, ensuring that your final products meet the highest quality standards.

By incorporating our rock sifting screens into your workflow, you’re not just saving time and resources; you’re elevating the overall efficiency of your projects while maintaining a commitment to environmental sustainability.

Why Choose Roy Manufacturing to produce your custom screens:

Roy Manufacturing is your premier business partner for producing top-tier rock sifting screens for your unique needs. With a legacy of over 65 years in the industry, Roy Manufacturing has solidified our reputation as a leader in precision machining, fabrication, and assembly services.

1. Expertise and Experience: Roy Manufacturing’s extensive history in producing perforated products speaks for itself. With a foundation laid by Roy O. Young over six decades ago, our company’s expertise has been honed through years of innovation, growth, and commitment to excellence. This experience translates into unmatched craftsmanship and an in-depth understanding of the intricacies of perforation production.

2. Customer-Centric Philosophy: Roy Manufacturing’s philosophy revolves around one simple principle: delivering exceptional customer service. Our company is dedicated to ensuring that each customer’s needs are not only met but exceeded. This commitment to service has been a driving force in our success, creating lasting relationships and instilling confidence in our clients.

3. Speed and Efficiency: In today’s fast-paced business landscape, time is of the essence. We recognize this and place a premium on efficiency. Our skilled and long-serving team is known for providing same-day quotes, and once your order is placed, you can expect delivery within just five days. This rapid turnaround allows you to move forward with your projects without unnecessary delays.

4. Customization Capabilities: No two projects are alike, and Roy Manufacturing understands this. With our state-of-the-art equipment and a team of experts, we are equipped to handle custom perforation projects tailored to your specific requirements. This level of customization ensures that your rock sifting screens are perfectly suited to your unique needs and application.

5. Diverse Materials Expertise: Whether your project demands stainless steel, aluminum, brass, copper, or other alloys, Roy Manufacturing has the know-how and experience to work with a variety of materials. Our adaptability allows them to meet the demands of various industries, providing solutions that are not only functional but also aesthetically pleasing.

6. Cutting-Edge Equipment: Roy Manufacturing’s commitment to quality is reflected in our cutting-edge equipment. With a fleet of eight CNC-controlled turret punch presses, ranging in punching capacity, we have the tools necessary to produce perforated materials with precision and consistency. Our pre-production and post-production equipment further ensure that every detail is attended to.

7. Comprehensive Industry Applications: Our perforated materials find their place in diverse industries such as architecture, automotive, agriculture, and filtration systems. Our versatility in serving multiple sectors attests to their expertise in delivering solutions that transcend boundaries.

Understanding Rock Sifting Screens:

Understanding Rock Sifting Screens: