Advantages of Perforated Metal in HVAC

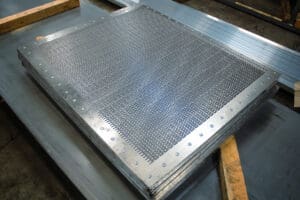

Perforated metal has been a quiet powerhouse in HVAC design for years. But today, its role is adding more value than ever. Many of the most meaningful advancements to meet rising demands for cleaner air, quieter systems, and energy efficiency are happening behind the scenes: in the grills, screens, diffusers, and housings that make modern systems efficient and reliable. In other words, perforated metal is proving to be one of the HVAC industry’s most powerful tools.

At Roy Manufacturing, we’ve seen firsthand how the right perforation pattern, material choice, and precision fabrication can transform HVAC outcomes. We’ve built our reputation on providing the precision, customization, and speed that the industry requires to perform at its best.

How Perforated Metal Drives Innovation in HVAC

1. Enhancing Airflow Efficiency

At its core, HVAC is about controlling airflow. Even small inefficiencies can increase energy consumption and reduce system effectiveness. That’s why perforated metal is essential in HVAC. Its consistent patterns help units run more efficiently by regulating air distribution, reducing pressure drop, and ensuring smoother transitions throughout the system.

At Roy Manufacturing, we deliver this high-level performance with tight-tolerance tooling, advanced CNC punching, and fully customizable open-area percentages. This allows HVAC designers to dial in airflow requirements with incredible accuracy. Whether a project needs micro-perforations for fine filtration or large-diameter patterns for high-volume ventilation, our team can produce the exact spec – and fast.

2. Supporting Indoor Air Quality

Indoor air quality (IAQ) continues to be a priority, especially in environments like hospitals, schools, and manufacturing facilities. Perforated metal supports IAQ by acting as a key component in filtration systems, air scrubbers, and protective housings.

This is where Roy Manufacturing’s material flexibility becomes invaluable. We manufacture perforated stainless steel, aluminum, galvanized steel, and specialized alloys. Our ability to produce corrosion-resistant, structurally stable filter screens ensures they hold up to constant airflow, moisture, and chemical exposure – something synthetic alternatives can’t match.

3. Advancing Acoustic Control

Noise reduction has become a defining feature of modern HVAC system designs. In large commercial or industrial facilities, these systems can be a significant source of unwanted noise. Using perforated metal in HVAC can help reduce this noise. The perforations allow soundwaves to pass through and be absorbed by the insulating material behind them. This leads to a dramatic reduction of noise from ducts, vents, and mechanical rooms.

At Roy Manufacturing, our precision punching tools produce patterns that meet the acoustic engineering requirements for optimal noise absorption. Our team frequently collaborates with engineers to develop custom perforated solutions that integrate seamlessly with insulation systems to create quieter, more comfortable spaces.

4. Long-Term Durability

HVAC systems require components that can withstand temperature changes, moisture, vibration, and exposure to the elements – especially in rooftop and industrial installations. Compared to plastic or composite materials, perforated metal offers unmatched durability and longevity. Its strength ensures housings, screens, and guards resist warping, cracking, and UV degradation.

Roy Manufacturing strengthens this advantage even more by using high-grade materials, specialized coatings, and fabrication processes engineered to increase longevity. When system reliability is non-negotiable, perforated metal – and the right manufacturing partner – make all the difference.

5. Sustainability and Recyclability

Today’s HVAC market demands sustainability, and perforated metal meets those demands. It’s recyclable, durable, and helps reduce energy consumption through improved airflow efficiency. Using perforated metal in HVAC is an ideal choice for projects seeking LEED certification or aiming for a lower carbon footprint.

Roy Manufacturing adds value here as well. Because we custom-produce perforated components to a project’s exact specifications, we help reduce material waste and ensure long-term use – both wins for sustainability.

Why HVAC Innovators Choose Roy Manufacturing

The true power of perforated metal lies in its ability to be customized. No two HVAC systems are identical, and neither are their performance demands. At Roy Manufacturing, we’ve spent decades providing custom solutions that mechanical engineers, fabricators, and contractors can rely on.

With rapid quoting, short lead times, and a team that understands the nuances of HVAC design, we’re able to deliver the high-accuracy custom perforated metal components you need quickly, accurately, and at scale. Contact us today to learn how our precision tooling and exceptional customer service make us a trusted partner for the HVAC industry.