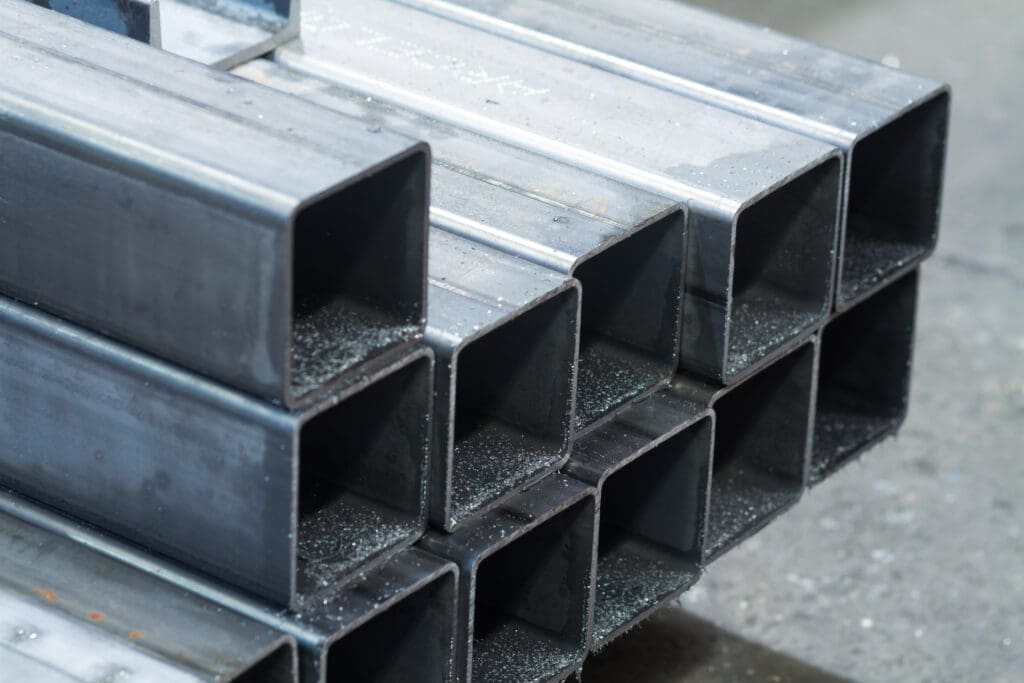

About Carbon Steel

Carbon steel is an iron-carbon alloy containing up to 2.1% carbon. It can be crafted from a mix of recycled steel, freshly sourced steel, or a blend of both. It’s relied upon for its high strength, low cost, and versatility. Rust and corrosion can be an issue. This material is used in construction, automotive, and manufacturing.

Composition

The composition of this material varies depending on its type, but in general, carbon steel is primarily composed of iron and carbon. The carbon content can range from about 0.05% to 2.1% by weight. In addition to carbon, it may also contain other elements, such as manganese, phosphorus, sulfur, and silicon, which can affect its properties. For instance, low-carbon steel typically contains up to 0.3% carbon and 0.6% manganese, while high-carbon steel can have a carbon content of 0.6% to 1.0%

Production Process

Freshly sourced or virgin steel is created by blending iron ore, coke (formed by heating coal without air), and lime in a blast furnace heated to approximately 1650 °C. The molten iron derived from the iron ore absorbs carbon from the burning coke, while the remaining impurities unite with lime to create slag, which rises to the surface of the molten metal for removal.

After the initial production process, the molten steel contains approximately 4% of carbon by weight. A process called decarburization is employed to achieve the desired carbon content. In this method, oxygen is introduced to the melt, oxidizing the carbon in the steel and generating carbon monoxide and carbon dioxide.

Types

This metal can be classified into three main types based on its carbon content: low-carbon, medium-carbon, and high-carbon.

- Low-Carbon Steel:

- Carbon Content: Less than 0.25%.

- Properties: Low hardness, high ductility, toughness, machinability, and weldability.

- Applications: Widely used in various applications such as automobile components, structural shapes, pipes, food cans, cookware, and concrete reinforcement bars

- Medium-Carbon Steel:

- Carbon Content: Between 0.25% and 0.60%.

- Properties: Medium strength, low hardenability, medium ductility, toughness, and wear resistance.

- Applications: Suitable for machine or car parts, railway tracks, train wheels, crankshafts, gears, pressure vessel tanks, and automotive parts.

- High-Carbon Steel:

- Carbon Content: Between 0.60% and 1.5%.

- Properties: High hardness, strength, low ductility, and high wear resistance.

- Applications: Commonly used in cutting tools, springs, high-strength wires, and components requiring high wear resistance and hardness.

Each type has distinct properties and is suitable for various applications based on its carbon content and alloying elements. The choice depends on the application’s specific requirements, such as strength, hardness, and machinability.

Despite its strength, this metal is susceptible to rust and corrosion when exposed to moisture over time. Even high-carbon steels will rust if not adequately protected. This is due to the higher iron content than other steels, making it prone to oxidation and corrosion. Parts can be coated with protective layers or finishes, such as paint, oil, or other corrosion-resistant coatings, to prevent rust.

Not sure which material is best for your project?

If you’re trying to decide between various materials and are unsure which solution will be best for your budget and application, contact Roy Manufacturing. Our professional team is here to help you select the perfect material to bring your blueprints to life. From metal perforation to precision laser cutting, we can do it all.