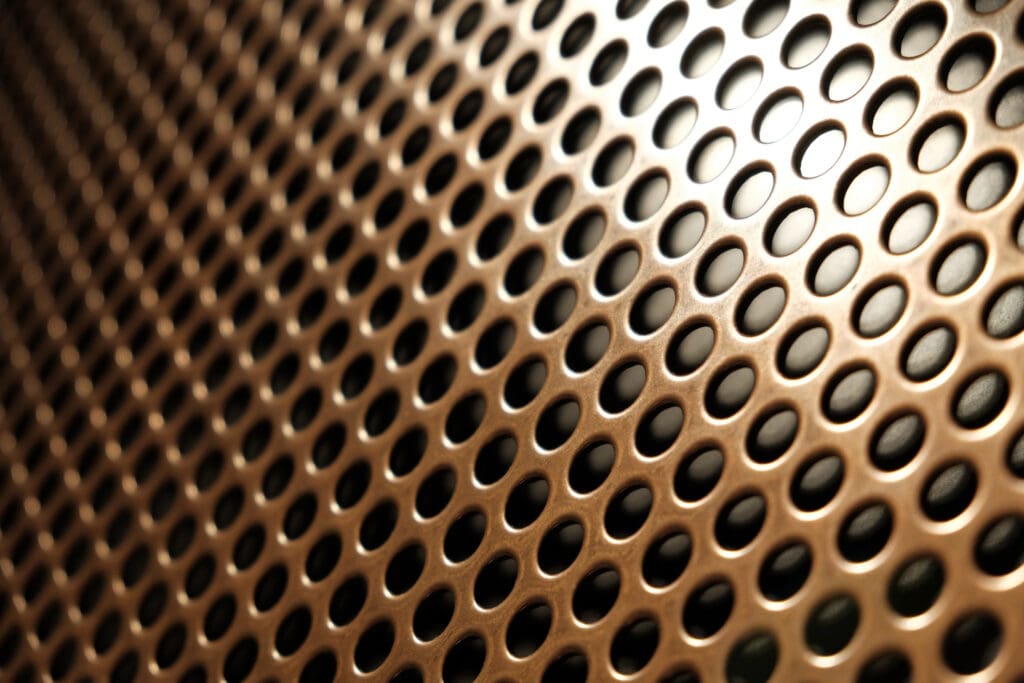

About Bronze

Perforated metal panels offer a unique blend of functionality and aesthetics, and when crafted from bronze, they lend a timeless elegance to architectural projects. Custom perforated bronze panels are increasingly sought after for their durability, versatility, and distinctive appearance. In this guide, we delve into the chemical composition of bronze, explore its common applications in perforated panels, weigh the pros and cons of choosing bronze for your project, and provide essential information for buyers considering this material.

Chemical Composition of Bronze

Bronze, historically revered for its beauty and strength, is an alloy primarily composed of copper and tin. The specific composition can vary, with additional elements such as zinc, aluminum, or phosphorus sometimes included to enhance certain properties. The typical composition of bronze used for architectural applications, including perforated panels, is approximately 90% copper and 10% tin. This alloy balance contributes to bronze’s unique golden hue, corrosion resistance, and structural integrity.

The chemical makeup of bronze makes it naturally resistant to corrosion, particularly in outdoor environments where exposure to moisture and air can accelerate metal degradation. This corrosion resistance makes bronze an excellent choice for long-lasting architectural features, including custom perforated panels.

Common Applications for Perforated Bronze

Custom perforated bronze panels find diverse applications across architectural, interior design, and functional purposes. Some common uses include:

1. Building Facades: Bronze perforated panels can be used as decorative facades, offering visual interest while providing ventilation and shade.

2. Interior Design Elements: They are employed in interior design to create partitions, wall cladding, and ceiling features, adding warmth and sophistication to spaces.

3. Furniture and Fixtures: Bronze panels are utilized in furniture and fixtures, such as room dividers, decorative screens, and ornamental accents.

4. Landscaping: In outdoor settings, bronze panels are integrated into landscape design and used for privacy screens, trellises, and decorative garden features.

Pros and Cons of Perforated Bronze

Advantages:

Perforated bronze panels are often selected for many of the benefits they provide:

- Aesthetic Appeal: Bronze exudes a classic, luxurious look that ages gracefully, developing a natural patina over time.

- Durability: Bronze is a robust material that withstands harsh weather conditions and maintains its structural integrity over decades.

- Malleability: It can be easily formed into intricate patterns and shapes, making it ideal for custom designs and perforations.

- Corrosion Resistance: Bronze’s natural patina acts as a protective layer, reducing the need for frequent maintenance.

Disadvantages:

Before selecting bronze as the choice for your perforated panels, consider the following:

- Cost: Bronze is more expensive than other metals, making it a premium choice for projects with specific aesthetic requirements.

- Weight: Bronze is denser than materials like aluminum, which may affect transportation and installation logistics.

- Surface Finish: While the natural patina is attractive, it may not suit every design aesthetic, requiring periodic maintenance to preserve or alter its appearance.

Determining if Bronze is the Right Material for Your Project

Our professionals at Roy Manufacturing can help you decide if bronze is the best material for your perforated metal project. Here are some examples of information we’ll ask you to provide as we consult with you about your needs:

Design Specifications: Clearly define your project’s requirements, including panel size, perforation pattern, and finish. The installation location and environmental conditions may also make a difference for selecting the best material.

Budget: Evaluate the overall cost implications, including material, fabrication, and installation expenses.

Maintenance Expectations: Metals have a variety of maintenance requirements depending on their composition. Additionally, bronze metal’s patina will evolve over time.

Choose Roy Manufacturing for all your perforated metal needs.

Custom perforated bronze panels offer a compelling blend of aesthetics, durability, and functionality for architectural and design projects. With its rich history, chemical stability, and timeless allure, bronze continues to be a favored choice for those seeking to elevate spaces with bespoke metalwork. By understanding its composition, applications, pros, and cons, you can make informed decisions for incorporating custom perforated bronze panels into your projects, ensuring enduring beauty and performance. Contact our team at Roy Manufacturing today for more information and a free quote.